SERVICES

EAFT.6130.000 Fuel Tank Installation

Double the range. Reduce downtime.

KNPP "Helicopters-MI" performs professional installation of external additional fuel tanks EAFT.6130.000 on Mi-8, Mi-8MTV, Mi-8AMT helicopters and all their modifications. We carry out complete aircraft modification for the EAFT system, including necessary structural and layout changes.

Result: flight range increases by 2 times — up to 1,020-1,070 km without refueling.

Where and how is installation performed?

- At KNPP "Helicopters-MI" production base (Kazan)

- At helicopter operation site — mobile field team

Work duration — 7 days

Technical team — 5 certified specialists

Why is this profitable?

✅ Less downtime — more flights

You can combine EAFT.6130.000 installation with scheduled maintenance (MRO). Thanks to close cooperation with aviation repair and MRO organizations throughout Russia, we ensure precise logistics, schedule coordination and minimum delays.

✅ Two modernizations at once — in one time

In Kazan, we work jointly with LLC "Tuzlar Interior Group", which allows simultaneous execution of:

- External fuel tank installation

- Cabin modernization (VIP, passenger, medical or combined)

Result: doubled outcome — increased comfort and extended flight range with minimum downtime.

What's included in the service:

- Preparation and modification of aircraft structure for EAFT.6130.000

- Fuel tank installation (585 l or 720 l)

- Fuel system functionality check

- Personnel training (on request)

- Supporting documentation by bulletin

Ready to expand your mission radius?

Contact us — we will calculate the optimal EAFT.6130.000 installation plan considering your geography, MRO schedule and flight tasks.

EWL.4011.000 Emergency Water Landing System Installation

Water safety — no compromises

.jpg)

KNPP "Helicopters-MI" performs complete installation of certified emergency landing system EWL.4011.000 on Mi-8, Mi-8AMT, Mi-8MTV helicopters and their modifications. Included: engineering modification, installation, testing, technical documentation delivery.

EWL.4011.000 keeps helicopter afloat for up to 30 minutes — sufficient for emergency evacuation of crew and passengers after water landing.

Where and how do we install?

- At KNPP "Helicopters-MI" base in Kazan

- At helicopter operation site (field team)

Work duration — up to 14 days

Technical personnel — 6 highly qualified specialists

What's included in modification:

- Front and main pontoon installation

- Gas-filled block and control system installation

- Electrical activation system connection

- Testing, commissioning, operation introduction

- Complete supporting documentation delivery (by bulletin № ТМ.2700-БУ-Г)

Safety without unnecessary downtime

KNPP "Helicopters-MI" cooperates with aviation repair and MRO organizations throughout Russia. Therefore, you can combine EWL.4011.000 installation with scheduled maintenance — this saves time and reduces helicopter downtime.

Comfort and safety — simultaneously

In Kazan, we also offer comprehensive interior modernization, jointly with LLC "Tuzlar Interior Group". You can in one visit:

- update or transform cabin (VIP, medical, passenger, combined)

- install emergency landing system

- exit with helicopter at new mission and flight readiness level

2-in-1 solution: comfort and safety without increasing downtime.

Ready to enhance your flight safety?

Submit request — we will select optimal configuration and installation schedule for EWL.4011.000 system according to your fleet tasks.

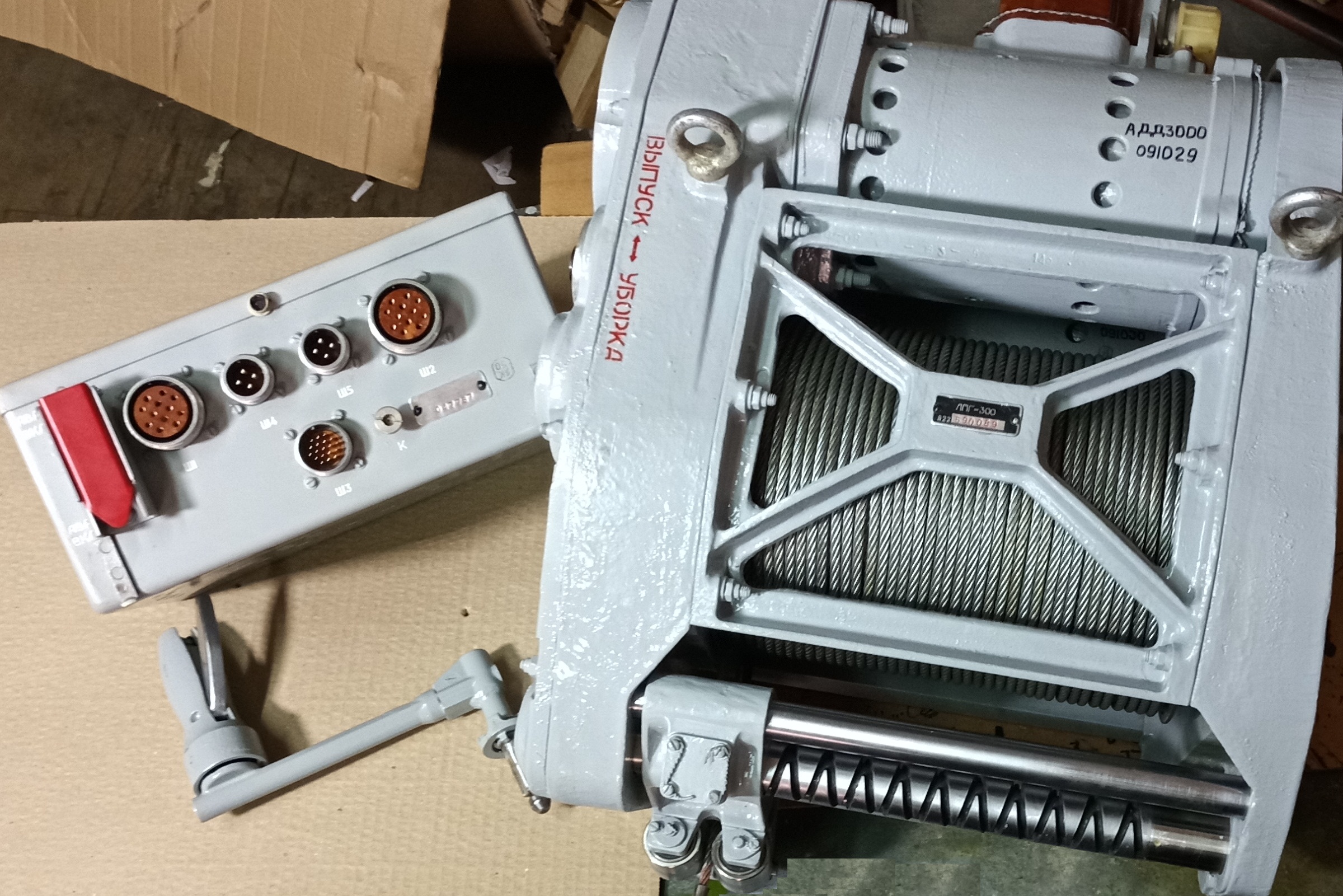

CWS-300 Cargo Winch Installation

Works where landing is impossible

KNPP "Helicopters-MI" offers complete service for CWS-300 cargo winch system installation on Mi-8AMT and Mi-8MTV-1 helicopters, including engineering structure modification and commissioning works.

CWS-300 allows lifting and lowering loads up to 300 kg, as well as evacuating people when landing is impossible — for example, in mountainous terrain, over forest, on water or in emergency situations.

Where and how is installation performed?

- At KNPP "Helicopters-MI" production base (Kazan)

- At helicopter operation site — field team

Work duration — by agreement (average up to 7 days)

Certified specialists involved

Technical documentation and operation introduction certificate issued

Purpose and capabilities

CWS-300 system provides:

- Load lifting and lowering up to 300 kg

- People evacuation from board (up to 2 people at once)

- Operation in four speed modes

- Remote control via ergonomic console

- Reliable operation at altitude up to 50 meters in hover mode

Why install CWS-300?

- Search and rescue operations

- Work in hard-to-reach areas

- Medical evacuation and casualty extraction

- Loading/unloading from small vessels, platforms, high-rise objects

- Humanitarian and UN missions with limited landing areas

Want to expand your helicopter capabilities?

Submit request — and we will calculate installation terms, offer CWS-300 kit and perform complete modification of your aircraft for any tasks: from emergency services to VIP missions.

External Cargo Suspension System Installation

Reliable transport up to 4.5 tons — right under fuselage

KNPP "Helicopters-MI" performs installation of 8MTV.9613.000 external suspension system on Mi-8MTV-1 helicopters, including all works on structure modification for new equipment.

System designed for suspension and transport of loads up to 4-4.5 tons, including their precise delivery and drop in hover mode — without ground personnel involvement.

Purpose and advantages

External suspension system with VT-DG6 locks is used for:

- Transport of construction, industrial-cargo and humanitarian loads

- Aviation construction and installation operations in hard-to-reach areas

- Emergency services, Rosnekhaz, geological exploration, energy tasks

- Rapid cargo delivery in emergency situations and disaster relief

Structure and control

System includes:

- 2 VT-DG 6 locks (upper and lower)

- Power slings (4 pcs)

- Extension cables (6 pcs)

- Guard and suspension frame kit

- Onboard "VECTOR" weight measurement system

- Lock power and control system

Lower lock control via portable console — through main and backup channel, allowing precise cargo release without cable drop and ground intervention.

Ready to expand your helicopter cargo capabilities?

Contact us — we will calculate suspension configuration for your mission type and perform installation in shortest terms.

Design Bureau and Aviation System Engineering

From ideas — to engineering solutions for helicopters and aircraft

KNPP "Helicopters-MI" provides complete services for aircraft system, unit and structural element design, including fuselage components, cabin systems, layouts and airframe modernization development.

.png)

We offer individual and serial engineering solutions for both military and civil helicopters, and ensure creation of complete supporting design documentation.

What we design:

- Airframe and fuselage structural units and parts

- Load-bearing structure and skin elements

- Equipment mounting and modular integration systems

- Layout and interior of VIP cabins, medical and passenger modifications

- Modernization and structure lightening complexes by technical specification

Design objectives:

- Mass and strength optimization of structure

- Flight and aerodynamic characteristics improvement

- Cabin adaptation to customer needs: VIP, cargo, medical, universal

- Certification procedure support and production preparation

Work formats:

- Conceptual design

- Detailed design and calculations

- Design and engineering solution development by specification

- Complete design documentation package creation according to OST and GOST

History and experience

KNPP "Helicopters-MI" Design Bureau is one of the oldest in Russian helicopter industry. It traces its history to 1946 and participated in development of key domestic aviation models:

- Mi-1, Mi-2, Mi-4, Mi-6

- Mi-8, Mi-14, Mi-18, Mi-19

- Mi-38 and their modifications

Accumulated experience allows us to offer effective engineering solutions considering modern requirements for reliability, resource and operational safety.

Need a project for your task?

We will develop individual solution for your aircraft — from concept to ready documentation package and production support. Submit request, and our engineers will contact you

Helicopter Cabin Modernization

Comfort. Style. Functionality.

KNPP "Helicopters-MI" professionally performs development, production and installation of modern helicopter cabins, including complete reconfiguration, technical equipment and interior design for any tasks: VIP, passenger, medical, transport and convertible (transformable) solutions.

What we offer:

Individual interior solutions:

- VIP cabin design project development

- Modern noise and sound insulation layout and installation

- Fuselage external painting scheme creation

- Design documentation and 3D visualization preparation

Transformer cabin (convertible interior):

- Quick configuration switching from VIP to passenger or cargo

- Adaptation for different mission types without cabin panel replacement

- Perfect for commercial, corporate and government customers

Modernization and restoration:

- VIP interior repair and restoration

- Composite element replacement or restoration

- Modern material and modular scheme application

- Cabin ergonomics and aesthetics improvement

Service:

- Warranty and post-warranty service

- Technical repair of cabin elements and interior systems

- Post-delivery support: operational consultations, field teams

Completed projects:

- 2023 — Mi-8 passenger cabin modernization for "Polar-Avia" airline, Magadan

- 2025 (in progress) — cabin production and installation in transformable version on Mi-8MTV-1 by order of CAPITAL GROUP (Moscow) and Nizhny Novgorod region government

Comfort tested in flight

Each project is combination of aviation safety, premium comfort and engineering precision. Cabins from KNPP "Helicopters-MI" serve long, look modern and adapt to customer tasks.

Contact us — and we will develop interior worthy of your mission.